About

I am currently working as a CAD Designer at Real Time Solutions Pvt. Ltd. I have also been around 3D printers and other fabricating tools through out my undergraduate life. I have also been working on Augmented Reality using Python.

Mechanical Engineer

Specialization in Design and Manufacturing

- Phone: +9779843478621

- Birth Place: Lamachaur, Pokhara-16, 33700, Nepal

- Degree: Bachelor in Mechanical Engineering

- Email: prashilrajshrestha@gmail.com

- Freelance: Available

Happy Clients

Projects Completed

Hours Of Support Consulting

Collab with other Engineers/Makers

Resume

Sumary

Prashil Raj Shrestha

Innovative and deadline-driven CAD Designer with 3+ years of experience designing and developing user-centered design from initial concept to final, polished deliverable.

- Mahalaxmi-16, Lalitpur, NP

- +977-9843478621

- prashilrajshrestha@gmail.com

Education

NIST

2013 - 2015

High School

National School of Science and Technology (NIST), Kathmandu, Nepal

Bachelor’s in Mechanical Engineering (Design and Manufacturing)

2015 - 2019

Bachelor’s in Mechanical Engineering (Design and Manufacturing)

Kathmandu University, Kavre, Nepal

Professional Experience

Intern at Pro-Mech Minds and Engineering Solutions Pvt. Ltd.

April 2019 - June 2019

Kumaripatti, Lalitpur

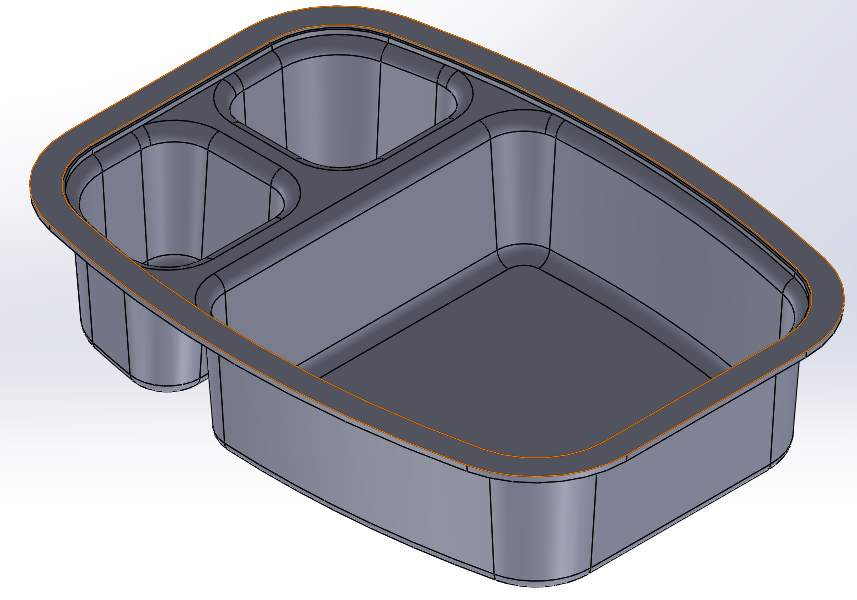

Work as a CAD Designer for 3 months Completed a project on ‘Food Packaging and Its Delivery using Biodegradable Material (like sugarcane bagasse)

Intern Researcher at Design Lab, Kathmandu University

July 2019 - October 2019

Dhulikhel, Kavre

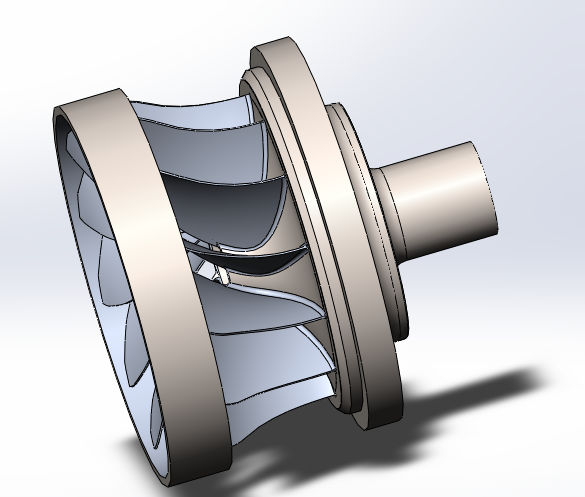

Research on Casting Simulation of 92kW Francis Turbine Runner

Mechanical Engineer at Real Time Solutions Pvt. Ltd.

Feburary 2020 - Present

Dhobighat, Lalitpur

Currently working as a CAD Designer/ Mechanical Engineer

Services

I am a CAD Engineer

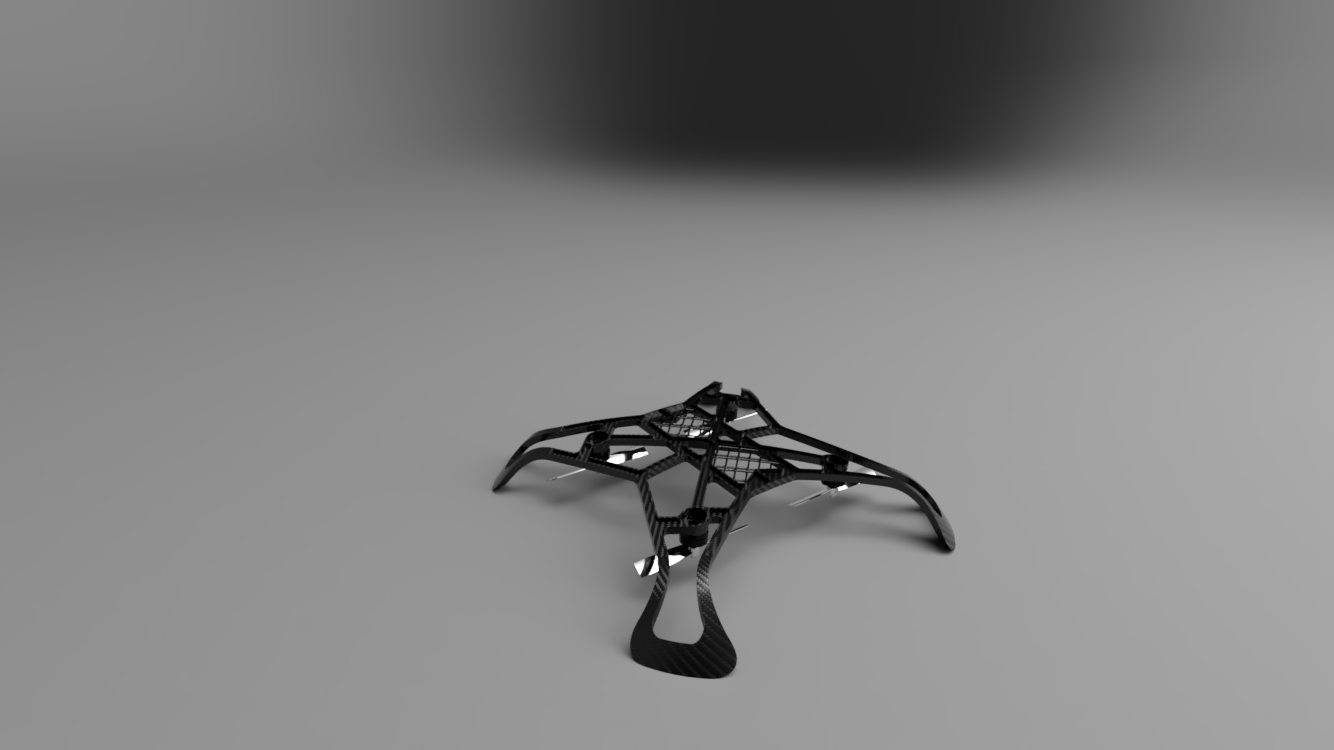

Product Design and Development

having a knowledge of multiple CAD software like Solidworks, Fusion 360, AutoCAD, etc. Done a lot of Product Design and Development during my undergrad and my professional life.

Research and Development

Done various works in the field of Advance Manufacturing and Machine Learning

Contact

Location:

Mahalaxmi- 16, Lalitpur, 44600, Nepal

Email:

prashilrajshrestha@gmail.com

Call:

+9779843478621